AUTOHOME WORLD LEADER IN SOLD

QUANTITIES, FOR ITS IMPRESSIVE

MODEL RANGE AND INTERNATIONAL

DISTRIBUTION NETWORK.

|

Around the World |

AUTOHOME WORLD LEADER IN SOLD QUANTITIES, FOR ITS IMPRESSIVE MODEL RANGE AND INTERNATIONAL DISTRIBUTION NETWORK.

|

Around the World |

AUTOHOME WORLD LEADER IN SOLD QUANTITIES, FOR ITS IMPRESSIVE MODEL RANGE AND INTERNATIONAL DISTRIBUTION NETWORK.

|

Around the World |

WHY AUTOHOME?

AUTOHOME. When experience makes all the difference.

We have always been “number 1”. Not by chance. Because of our combination of imagination and “Made in Italy” quality.

The result is our roof tent, the first, the original and still the biggest seller.

Each Autohome tent is the product of our experience and the recommendations of adventurer travellers.

These two skills together have created the largest range of tents available. A catalogue that is constantly kept up to date to provide you with a tent that is perfect for your needs.

Quality, reliability, comfort and a large number of accessories.

We do everything to give you a good night’s sleep.

BECAUSE IT’S MADE IN ITALY

It is a great pride that Autohome is entirely in Italy, where deep are our roots and where we still feel strong culture of good taste and design. The quality and attention to detail expresses our passion for a successful product in the world.

BECAUSE AUTOHOME GUARANTEES

CERTIFIED QUALITY

Autohome is committed to constant research and innovation: the exceptional level of safety and quality is recognized by the prestigious International Certification of TÜV SÜD Rheinland, formal acknowledgement of the excellence of the biggest selling (and Original) tents in the world.

Most Autohome products have successfully passed the following tests: 1. Test to 3.8 standard of DIN 75302/02.91;

2. Test to 3.9.2 standard of DIN 75302/02.91;

3. Test to 3.9.3 standard of DIN 75302/02.91;

4. Test to 3.9.4 standard of DIN 75302/02.91;

5. Certificate number: AK 60024834 0001;

6. The authorities can check for forged certificates;

7. Professional buyers often select suppliers and products on the basis of quality/safety certificates;

8. End users prefer certified products because they are a “safer” choice.

WHAT IS CERTIFICATION?

It is the Quality License. The certification of owning the product quality.

The term "to certify" comes from the Latin certum facere, which means "to make certain, evident".

For this reason, to give maximum protection to the customer, the range of Autohome roof tents is certified and guaranteed to have passed the stringent tests required by TÜV SÜD and other impartial quality and product Certification Bodies.

Precisely the TÜV SÜD is the only certification that guarantees the quality of the tent and its safety while driving, and it has nothing to do with the ISO corporate certification.

WARNING

There are roof tents on the market that do not have any real product certification. Beware of certifications such as ISO 9001 that some sellers advertise, because they concern the company organization and are not at all a guarantee of quality and security of the tent you are going to buy.

On the contrary, Autohome roof tents have passed stringent quality tests of the materials used, carried out in the laboratories of qualified Bodies, including the German TÜV SÜD.

The ISO 9001-2015 is the certification granted to Autohome on the company management organisation.

BECAUSE IT IS SAFE

If you are looking for a roof tent, you can be reassured by the certificates awarded to Autohome, concrete proof of our commitment to consumers and our wish to continuously improve. The transparency of quality information, origin of materials and manufacturing systems are further incentives when weighing up your decision and choosing Autohome.

BECAUSE AUTOHOME GUARANTEES

5* YEARS OF WARRANTY AND QUALITY CERTIFICATION OF THE PRODUCT

Each Autohome product has been made with attention to the smallest detail, using the most suitable materials for its use.

Sixty years in manufacturing enable us to adopt the best tested materials for different climatic and travel conditions.

Our tough “Autohome Quality” controls guarantee a product without material or packaging defects.

(*)Guarantee

BECAUSE AUTOHOME IS THE ORIGINAL

The only Autohome range in the world is ours: the Original. The other vehicle tents are not AUTOHOME Originals but copies. Just check to see when they were first marketed.

A DAZZLING ARRAY OF FORMATS, COLOURS AND SIZES

Of course, once you have made your decision, your choices don’t end there. You can follow your personal needs and tastes by customizing the product you have chosen: select from a wide range of shell colours, all factory-made using Gelcoat®. Shells are not prepared in the paintshop. And the range of colours for the fabrics is just as large.

WHY CHOOSE AUTOHOME?

So, the initial question: why choose an Autohome tent? For any number of reasons: out of good taste for the excellent design, or for the quality of the fabrics, the easy opening and closing, or the numerous accessories, or its reliability, safety and comfort.

You can take your pick of reasons when choosing Autohome.

WHY AUTOHOME?

Because no copy can make you forget the original.

Quite a history, and an amazing story.

Being number 1 in sales means leading the market and facing the challenge of competitors and imitators.

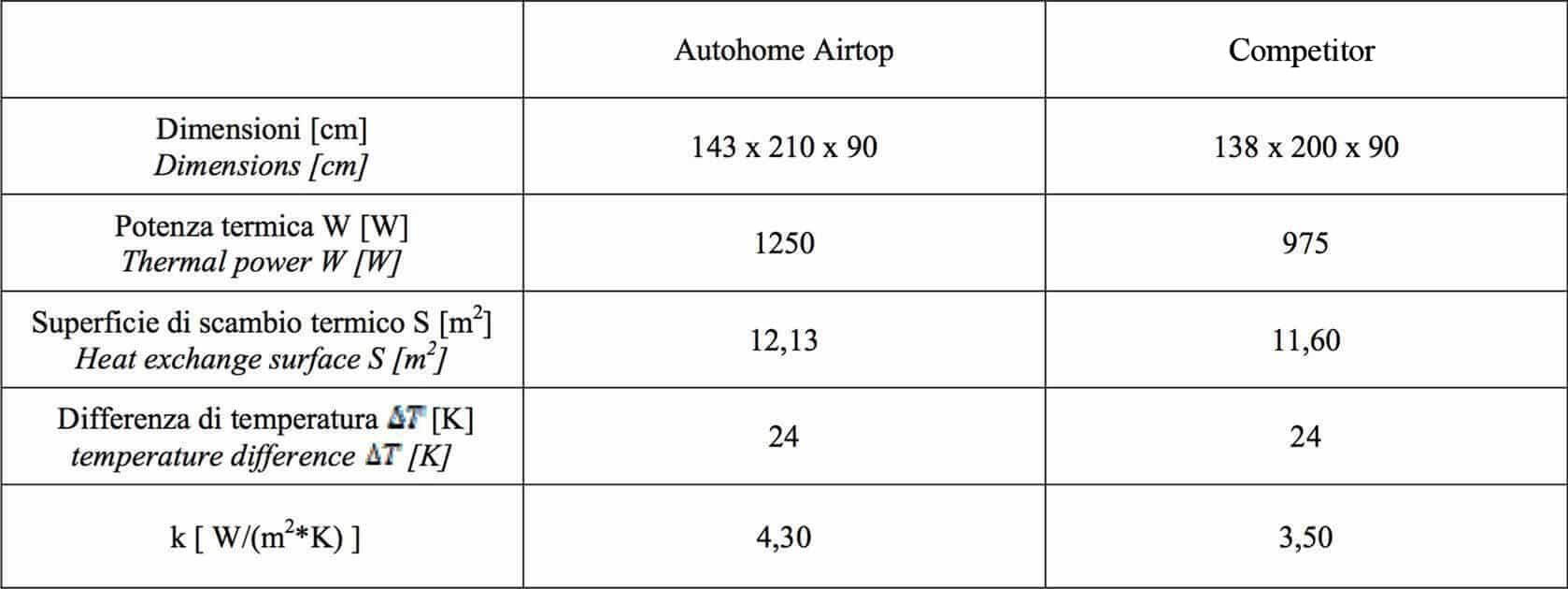

They do not always provide accurate figures. So we have decided to publish the true comparison between AUTOHOME® and a similar but competing product, so you can see the difference.

We have excluded all aesthetic considerations which are important but cannot be measured objectively, focusing on practicality and the functioning of the tent, and that means the fabric.

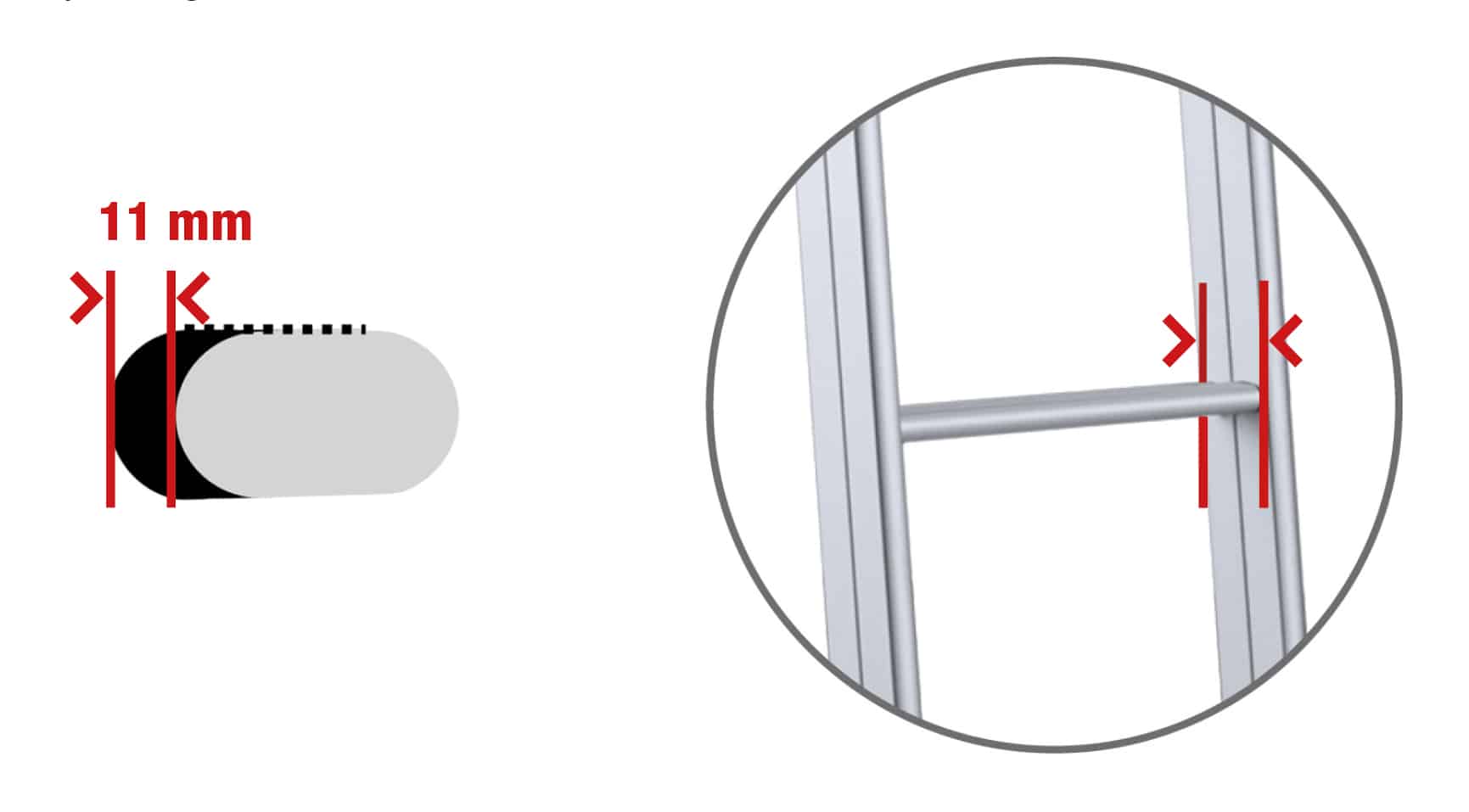

THE FABRIC

ANALYSIS OF A COMPETITOR’S FABRIC AND THE ORIGINAL AUTOHOME TENT FABRIC®

ESSENTIAL FEATURES

According to the Autohome technical team.

A bivouac fabric should not only be waterproof or “hermetically sealed”.

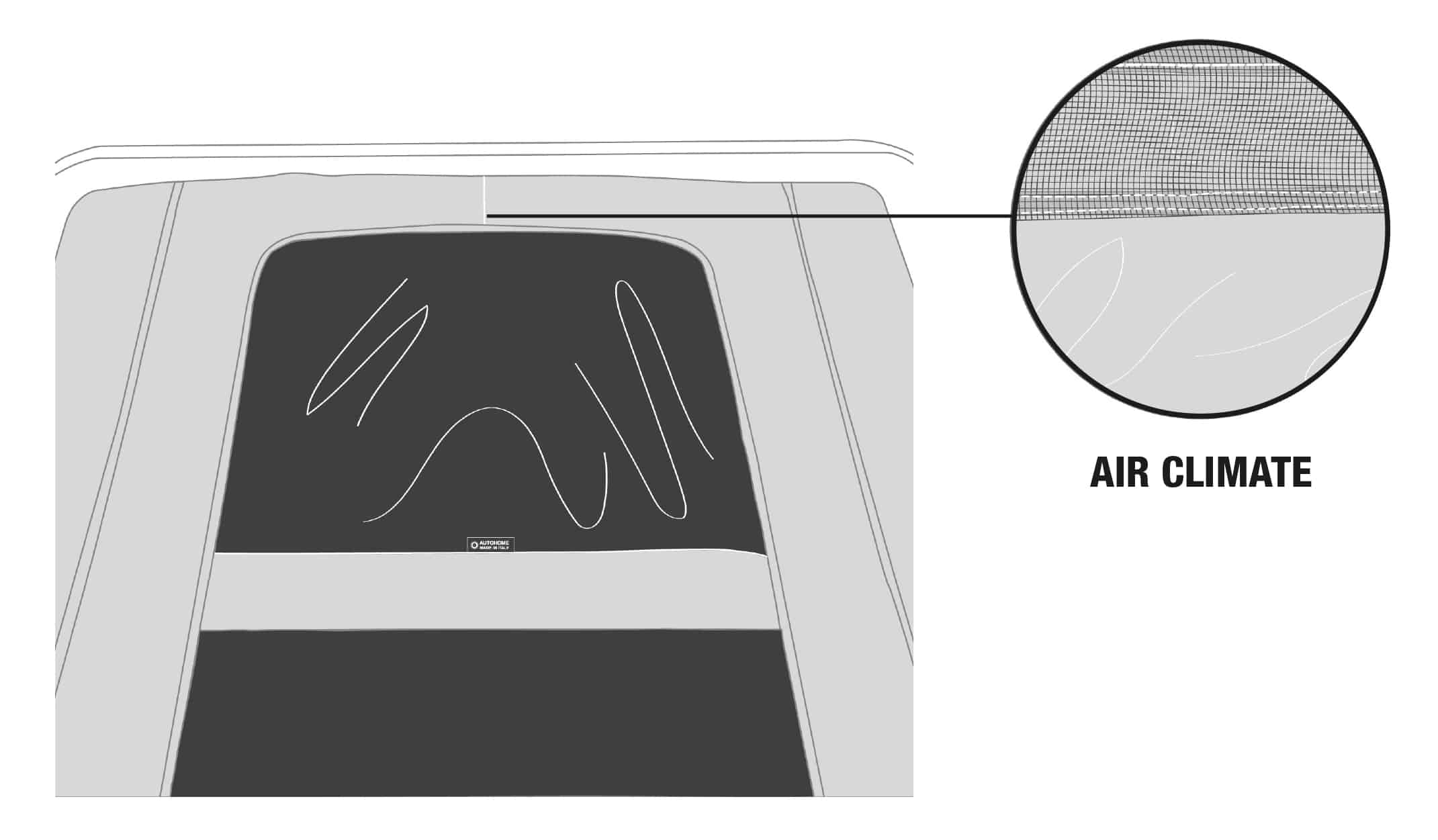

If it were only that, it would be suffocating. It should be breathable, especially because the sleeping area is very small. Every square centimetre of the fabric should help the natural change of air, for genuine wellbeing, which only a highly breathable fabric and the rapid expulsion of water vapour can provide. Technically speaking, a slightly breathable fabric increases condensation, moisture and heat, as any serious manufacturer knows.

BREATHABILITY

Test to measure the transit speed of the air from the inside to the outside. Method: UNI EN ISO 9237/97

The result is clear and unequivocal.

THE AIR DOES NOT PASS THROUGH THE COMPTITOR’S FABRIC.

This should not be overlooked because non-breathability increases moisture, condensation and heat, making the environment unhealthy.

Alternatives to breathable fabrics, such as moving the air with some mechanism, may help a little, but they do not improve comfort much and do little to contribute to health.

Healthy camping is impossible without breathability.

The lack of breathability is serious and compromises health: in normal conditions, at rest, the human body loses a third of a litre of water overnight, and – without breathability - this moisture is trapped inside the tent, creating droplets on the inner walls.

The second attempt to solve the problem adopted by the competitor is to increase the number of zips and openings, to ventilate the environment. But this means you are sleeping in contact with the outer environment, which may cold, be lit up and it may be raining.

WHEREAS AUTOHOME DRALON®, A HIGHLY BREATHABLE FABRIC, ALLOWS THE TENT TO “BREATHE” NATURALLY.

This is the essential feature of the extraordinary quality of the fabric used by Autohome.

Herat, moisture and condensation can escape from the tent naturally: 24/7. A precious fabric and a must for Autohome®, which has used it since 1980, despite the extra cost.

WATERPROOFING

Test that measures wettability when a fabric is used vertically, expressed from 0 to 5. Method: UNI EN ISO 4920/13

The competitor’s fabric becomes wetter and its stitching is less secure. A plasticized, dry fabric is more rigid and difficult to stitch: the holes made by the needle tend to stretch due to the tension and traction of the tent, so rainwater can get in. The competitor’s tent is shown with dangerous stitching where the fabric is attached to the shell.

Trying to tape over the holes does not help: and proper maintenance with resin or silicone needs to be repeated often.

AUTOHOME DRALON® FABRIC IS HIGHLY WATER RESISTANT. THE FIBER IS SOFT AND COMPATIBLE WITH STITCHING, AVOIDING PROBLEMS. THE STITCH HOLES REMAIN MINUTE AND DO NOT LET IN RAINWATER. THE STITCH THREAD NATURALLY EXPANDS IN THE RAIN COVERING THE HOLES ENTIRELY.

HEATPROOFING

Test that measures the heat resistance of the fabric in relation to heat loss from the tent. Method: UNI EN 31092/12

The test shows that the competitor’s fabric heats up more.

WATER VAPOUR TRANSMISSION COEFFICIENT

Test that measures how much water vapour passes through one square metre of fabric in 24 hours. Method: UNI 9278/88

The result is clear and unambiguous! There is no comparison: 536 g/d*m2 against 6288 g/d*m2.

An advantage for Autohome of 5752 g/d*m2.

THE TESTS SHOW THAT THE COMPETITOR’S FABRIC HEATS UP AND RETAINS WATER VAPOUR.

That’s why the competitor’s tent is full of openings, diminishing privacy.

Fitting an anti-condensation stack to the roof of the tent is a tacit admission (never mind the aesthetics) that the fabric is not breathable.

The stack is fitted to a hole in the roof, another way rainwater can get in.

THE TESTS SHOW THAT, ON THE CONTRARY, AUTOHOME® DRALON ALLOWS THE HEAT TO ESCAPE AND ENABLES THE CIRCULATION OF AIR, BOTH QUALITY REQUIREMENTS.

AND YOU DON’T NEED A STACK OR PLENTY OF OPENINGS, RUINING COMFORT AND PRIVACY.

PROBLEM: CONDENSATION AND HEAT SOLUTION: THE AUTOHOME TENT

by the Autohome technical team

Condensation is a natural phenomenon in camping tents.

When the temperature falls to lower than the temperature inside the tent, the moisture in the air condenses and clings to the inside walls of the tent in the form of droplets.

Generally, this happens in the evening, at night or at altitude when the fabric is fresher. The result is that the environment inside the tent becomes unhealthy and uncomfortable, unsuitable to a proper night’s sleep.

We say generally because condensation can be drastically reduced by using quality materials.

Dual layers really only hide the droplets from view and do nothing to prevent condensation.

Factors that lead to condensation include:

- the moisture in human breath

- hot air created during the day

- a rainy atmosphere, full of moisture

- body heat. Overnight our bodies generally lose about a third of a litre of water, in normal conditions of rest. And this water vapour needs to be allowed to escape, without forming puddles.

Recommendations to reduce condensation inside a tent include:

- keep the fabric taut, which is easy to do with Autohome and above all with Maggiolina models opened by handle. Moisture condenses and collects in the folds and wrinkles of the fabric.

- Ventilate the inside of the tent even when it rains, using the rain covers over the windows and doors.

- If the problem persists even after taking these actions, the fabric has lost its breathability, either because of dirt, dust or smog clogging up the pores. Clean the fabrics with shampoo (for example Marseilles soap).

The importance of breathability cannot be overstated.

Using fans or other gadgets, as competitors do, serves no purpose whatsoever as the test below shows. Essentially, these devices are just “commercial gadgets”, without any practical use, shunned by experts and appealing only to the inexperienced.

COMPARISON WITH A COMPETITOR: TEST IN A CLIMATIC CHAMBER

Tests carried out by the Certification and Analysis Centre, which works internationally on services to companies.

The staff comprises teams of engineers, physicists and microbiologists trained in applied research institutes working with European University research departments and other research centres.

AUTOMOTIVE DIVISION

Test set-up:

(* ) The competitor sample was equipped with a fan for air circulation within the same that has been turned on during the test. This fan is not compliant with Community regulations (it is not EU trademarked)

Description of the test

The test was carried out on two different samples to verify the exchange specified in ECE /TRANS219 REGULATION by calculating coefficient k as follows

A stove was placed inside both samples with two thermocouples in opposite corners of the ceiling to monitor the temperature. The climatic test involved creating a temperature of 8°C and, after stabilization of the environment inside the tents, the stove was switched to 31.5°C.

40 minutes later, the heat dispersal was measured in stable conditions.

The test was performed on two different samples in order to evaluate the heat exchange as defined by the ECE/TRANS/219 through the determination of the coefficient k is defined as follow:

W represent the thermal power dissipated by heather to maintain a constant temperature difference between the internal ad external environment of the sample;

S represent the heat exchange surface of the sample;

Dt temperature difference between inside and outside of the sample;

Within both samples it was placed a heater and two thermocouples to the two opposite corners of the ceiling to monitor the temperature. And a climate test by placing the environment at 8° C temperature and, once the expected stabilization of conditions even within the sample, the heater to bring the interior of the tent has been turned ‘was performed at 31.5°C.

After 40 min was detected the thermal power dissipated by the latter for the maintenance of the new climatic conditions. Having again awaited the stabilization of the same.

The results obtained are shown below:

A larger k coefficient k in the same conditions indicates greater heat exchange of the tent walls.

THE RESULTS ARE SURPRISING: WITHOUT USING A FAN OR OTHER DEVICE, DUE TO THE QUALITY OF THE FABRIC, THE AUTOHOME TENT EXPELLED MORE HEAT (24 HOURS A DAY, WITHOUT BATTERIES AND IN COMEPLETE SILENCE).

TEST DESCRIPTION 2

The test was performed on two different samples in order to evaluate the thermal exchange within the same by inserting a steam generator and evaluating after 20 min the presence or absence of condensation on the walls.

Test results: